Flat Honing and Lapping with Two-Wheel Machines

Measuring – Results

The thickness dimensions of the work pieces is measured directly on the machine using the centrally installed gauging during the work process. Tolerances of less than +/- 1 micron are economically possible, depending on the condition of the machine, the working wheels, the gauging probe and the type of the work pieces.

The parallelism of those surfaces in good conditions should lie within tolerances of less than 1 micron for a work piece of 100 * 10mm diameter on a machine with a working-wheel diameter of 1,000mm. Results have been known from practical experience where work pieces of diameter 300/100 * 8mm on a machine with a working-wheel diameter of 1,500mm can still be machined to the perfect co-planar dimension at under 2 microns. A fault can cost a great deal of time and money.

The surface quality of the work piece depends on the final load, the grain, the medium and the condition of the working wheels. Irregular surfaces bear witness to uneven progress between the working wheels, where you should also search for signs of a flatness fault. When using loose grains such as Si-C and B4C, the lapping surfaces are generally matte gray, but they satisfy the requirements in most cases. If diamond liquids or bound grains (fixed-grain wheels) are being used, the surface will appear bright and reflective, as if it was honed or similar to cross-grinding. In the latter machining method, the surfaces are easier to clean and check.

The measuring devices for both direct and indirect process measurement are well-known.

- indirect or in-process measurements are carried out by the central gauging probe which is permanently installed in the machine (most common procedure)

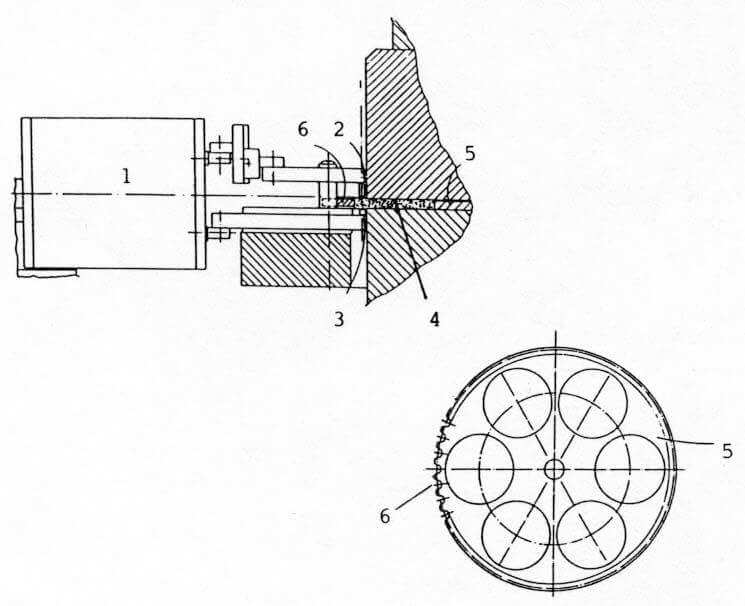

- Direct measurements on the work piece during the process from the outside can cause problems in terms of the wear on the gauging probe, reliability and soiling. (figure 34)

- Measuring device

- Upper gauging probe

- Lower gauging probe

- Work piece

- Work holding plate

- Toothing on work holding plate

Figure 34: Measuring device for direct measurement from outside

The following should be noted for direct measurements from outside: there is the problem of work pieces overhanging the outer diameter of the working wheels, and the related soiling and possible damage by the probe. It is therefore only possible to measure relatively large work pieces with greater exposure. It is also important to comment on the flatness or coarseness.